Do you want to know more about SMS medical fabric

Views:1712 Publish Time: 2022-06-20

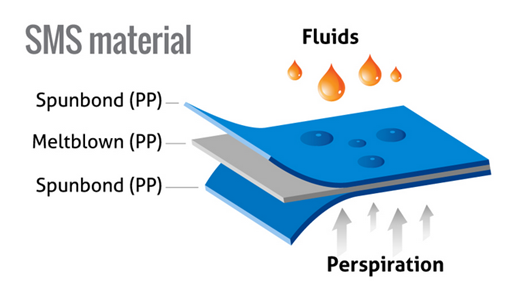

SMS non woven fabric (Spunbond + Meltblown + Spunbond Nonwovens is a composite non-woven fabric, which is a composite product of spunbond and meltblown. It has the advantages of high strength, good filtering performance, no adhesive, and non-toxic. At present, it is mainly used in medical and health labor protection products such as surgical gowns, surgical caps, protective clothing, hand washing clothes, handbags, etc. It is non-toxic and tasteless, highly effective in separating bacteria. Through special treatment of equipment, it can achieve anti-static, anti-alcohol, anti-plasma, water-repellent and water-producing properties.

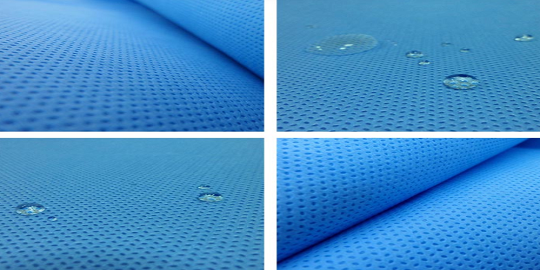

Advantages of sms non woven fabric

1. Lightweight: Polypropylene resin is used as the main raw material for production. The specific gravity is only 0.9, only three-fifths of cotton. It is fluffy and feels good.

2. Soft: It is composed of fine fibers (2-3D) and is formed by light-point hot-melt bonding. The finished product is moderately soft and comfortable.

3. Water-repellent and breathable: Polypropylene slices do not absorb water, have zero water content, and have good water-repellent properties. They are made of 100% fiber and are porous and air-permeable. It is easy to keep the cloth dry and easy to wash.

4. Non-toxic and non-irritating: The product is produced with FDA food-grade raw materials, does not contain other chemical components, has stable performance, is non-toxic, has no peculiar smell, and does not irritate the skin.

5. Antibacterial and anti-chemical agents: Polypropylene is a chemically blunt substance, not moth-eaten, and can isolate the corrosion of bacteria and insects in the liquid; antibacterial, alkali corrosion, and the strength of the finished product will not be affected by erosion.

6. Antibacterial property. The product is water-repellent, not moldy, and can isolate the bacteria and insects in the liquid from erosion, and is not moldy.

7. Good physical properties. It is made of polypropylene spun yarn and directly spread into a net and thermally bonded. The strength of the product is better than that of ordinary staple fiber products.